The Author

All text and illustrations on this website are copyright.

BALL TURNING

A lathe home made attachment

Ball Turning Tool With Completed Handles

This ball turning tool was made to a design published in Model Engineer's Workshop Issue 26 December 1994. The purpose was to make the ball handles for my Tool and Cutter Grinder.

The design is one which turns about a vertical axis and works well. However if I did this again I should probably make one of the type that pivots around a horizontal axis and fits into the tool post. Below is shown the 3 stages in making a ball handle. First cut two grooves of distance from the ends equal to the diameter of the ball to be made. Then turn the body of the handle down to give two parallel portions to hold in the chuck. The larger diameter is large enough for the chuck jaws to clear the large ball end and the smaller diameter is large enough to allow the jaws to clear the smaller ball end. This enables the blank to be held in the chuck for turning the balls on the ends of the blank.

Balls Ready for Taper - Shown with Holding Attachments

Turning the taper is difficult, as once the balls are turned, there seems to be little to get hold of in order to turn the taper. It is necessary to make two adapters. One, a simple female adapter to hold the small ball in a rotating centre. The second is a socket with a section milled out of it. This should be a sliding fit on the large ball, and once in the 3 jaw chuck should close on the ball to allow the handle to be driven for taper turning. Turning the taper is shown below. The ball is swung sideways and back through the slot in the socket adapter to mill, drill and tap for the bolt.

Preparing to Turn the Taper on The Handle

Ball Handles in Various Stages of Product

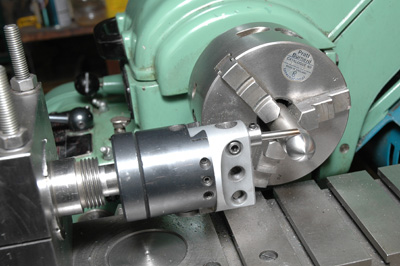

Up And Over Turning

I do like the "up and over" version of ball turning tools where the tool rotation axis is horizontal and at right angles to the lathe axis. When thinking about this concept, it occurred to me that these types of ball turners, are very similar to boring heads and I already had one of those. I therefore mounted it in my shop spindle and bolted it to the cross slide of the lathe as in the photo. The overhang looks impossible but it is unimportant as the forces are pushing the tool horizontally not vertically and the setup shown here works superbly.

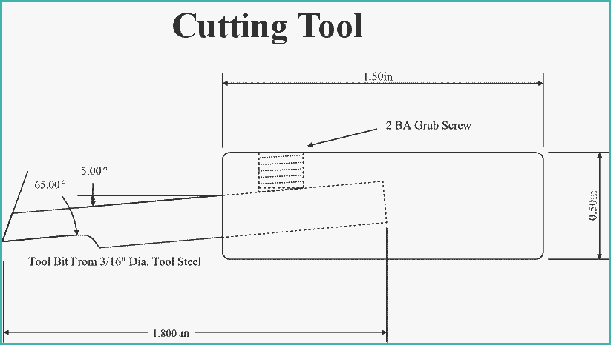

For those interested in this style of ball turning, I wrote an article on this in Model Engineer's Workshop - issue 133. I do find the system more adaptable however, if the clamping arrangement is fastened to a vertical slide. The dimensions of the tool bit are shown below :-

Using a Boring Head for Ball Production

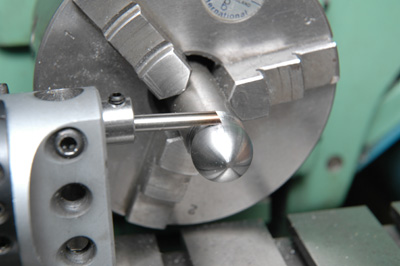

The Actual Cutting Tool

The Business End of the Boring Head